Sorry, as a bot-control measure, you need at least one post here before you can download. By asking that question, you now have the required permissions.... If you still have any problems, just let us know.

True aluminum or stainless would hold up I imagine, but the strength of a 3D printed metal part would be heavily dependent on what machine/process is used. They sell metal-filled plastic for home printers, which would not stand a chance I suspect. On the other hand, there are high-end commercial printers from companies like HP that can print metal that's as strong as the real McCoy. If you send it off to Shapeways or Xometry , etc., and had it done on a million dollar metal printer, I'm sure it would hold up, but that would probably cost a lot more than just buying the tool.

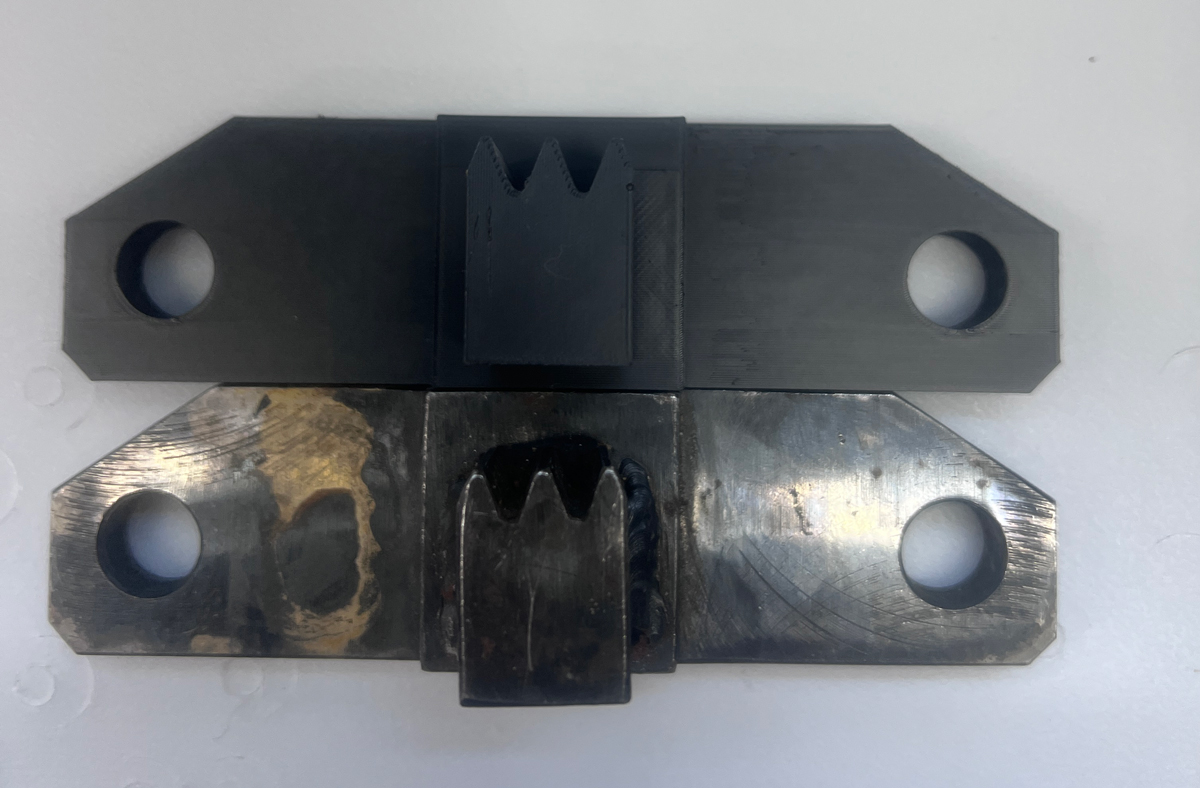

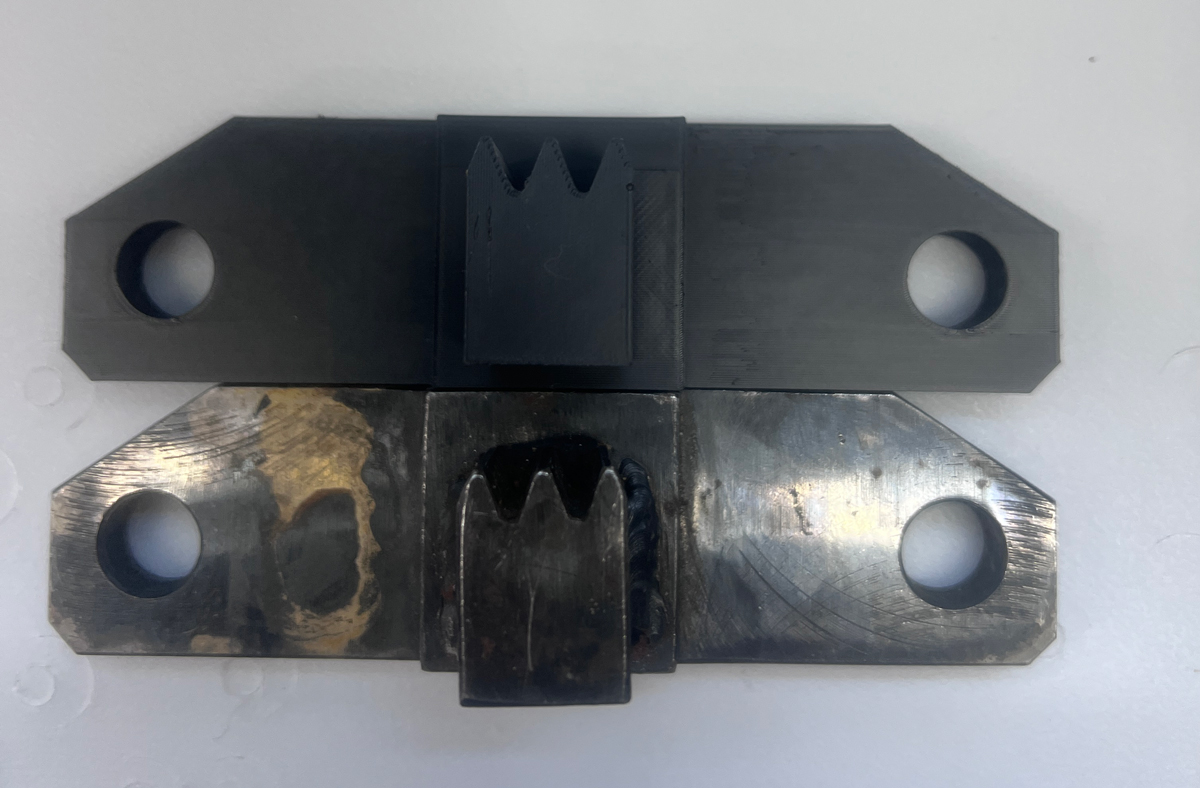

Please report back if it fits. Also, be aware I made this on special request to have a good model of it out there, but a typical 3D printer cannot make one strong enough to torque and untorque the front pully bolt -- it WILL break. It can still be useful to keep the motor from turning while working on belts/cams, etc.